-

What are the advantages of using two sets of stopping frames for the Tsuda Koma jet towel loom

2025-05-05The Tsudakoma jet towel loom has the following advantages when using two rows of warp stopping frames: 1. Improve fabric quality Correctly detecting broken ends: The warp and weft of towel fabrics usually have different tension and motion characteristics. Two sets of warp stopping frames can be set with different specifications of warp stopping pieces for ground warp and wool warp, which c

-

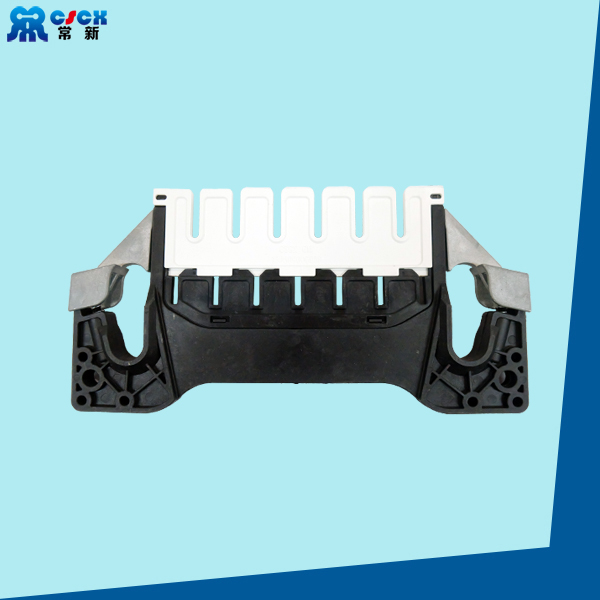

What are the characteristics of the 6-row warp stopping device used in Gamma looms

2025-04-28The 6-row warp stopping device used in Gamma looms has the following characteristics: 1. Trigger sensitivity: By fixedly connecting one end of the torsion spring to the trigger piece, when the warp state changes, it can quickly drive the trigger piece to change the angle, thereby triggering the warp stopping action in a timely manner, causing the loom to quickly stop running and effectively avoid

-

How to embody the support function of bracket in textile equipment

2025-04-21In textile equipment, the bracket is mainly used to support and fix textile components to ensure the smooth progress of the textile process. Its supporting role is mainly reflected in the following aspects: 1. supporting yarn winding: in the process of spinning and weaving, the bracket is used to support yarn winding, such as bobbins, reels, etc. By providing stable support, it can make the yarn

-

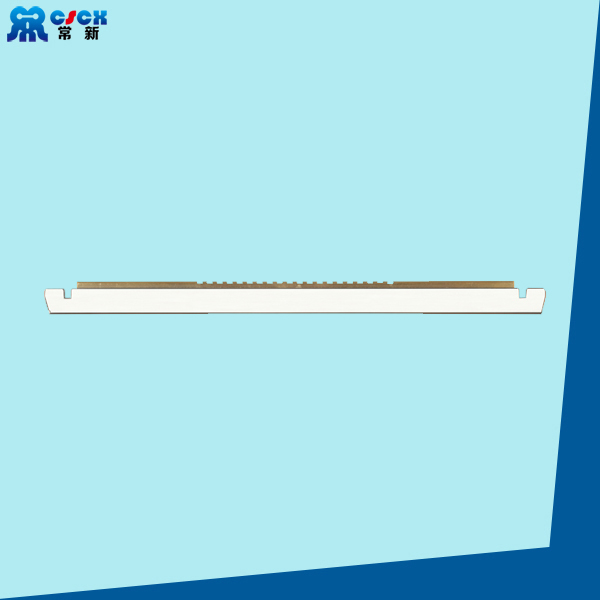

How to reduce raw material waste with textile equipment warp strips

2025-04-14Textile equipment warp strips can reduce raw material waste by correctly detecting broken ends, quickly locating problems, optimizing production processes, and other methods. The following is a specific introduction: 1. Correctly detect severed heads Choose the appropriate type: Based on the characteristics of textile raw materials and production processes, select warp stopping strips with

-

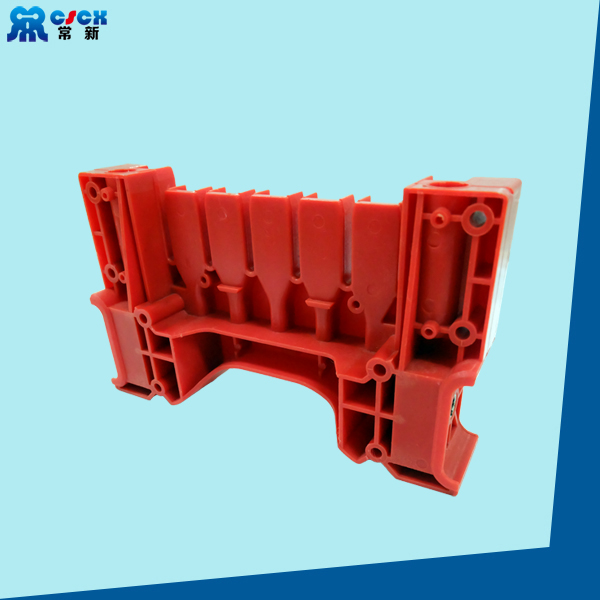

How to prevent fabric defects in menopause electrical box

2025-04-07The warp stop electrical box can prevent fabric defects mainly through the following working mechanisms: 1. real time monitoring of warp status: the warp stop electrical box works with the warp stop frame, and each warp passes through a warp stop. When the loom is in normal operation, the warp is in tension, and the warp stop is supported by the warp, keeping a certain distance from the warp stop

-

How to protect the warp stop strip of textile equipment

2025-03-31Textile equipment warp bars protect the equipment in the following ways: 1. prevent excessive wear of parts: during weaving, if the broken warp is not found in time, some parts of the loom, such as needles, shuttles, heald frames, etc., will continue to interact with the broken warp or fabric. This may cause these parts to bear abnormal friction, impact force and accelerate wear. The warp stop ba

-

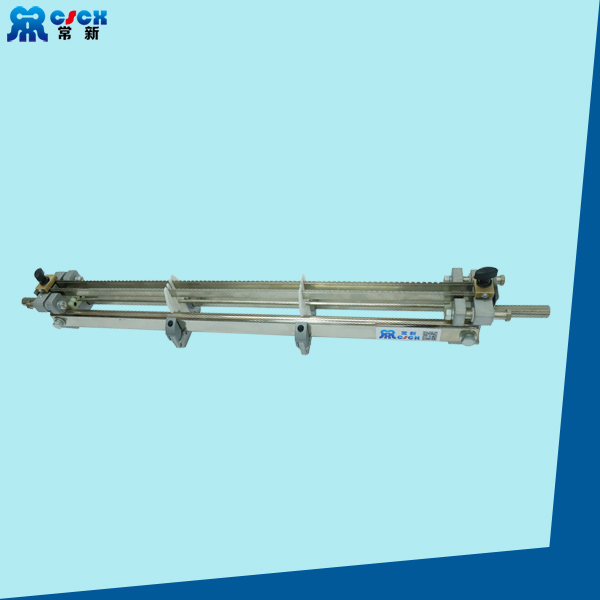

What is the working principle of the amenorrhea stand

2025-03-24The warp stop stand is mainly used to provide support, positioning and fixation for other parts of the warp stop stand. Its working principle is to indirectly realize the warp break detection function based on ensuring the correct position and state of relevant parts. The details are as follows: 1. support and positioning: the amenorrhea frame base provides stable support for the amenorrhea bar,

-

What are the advantages of menopause electrical box in operation

2025-03-17The menopause electrical box has the following advantages in operation: 1. the warp break position indication is clear: some warp stop electrical boxes have the function of single column display or segmented display, which can correctly indicate the position of the warp stop bar where the warp break yarn is located. For example, the warp stop electrical box with LED display technology, after the

Home

Home

Product

Product

Wechat

Wechat

Telephone

Telephone